Address:Shandong province Qingdao city Jiaozhou Beiguan Industrial Park, Shandong Road No. 36

Tel:0532-87286912

Fax:0532-87286913

Mobile:13708952663

ZipCode:266300

WebSite:http://www.htffbw.com

E-mail:1871245076@qq.com

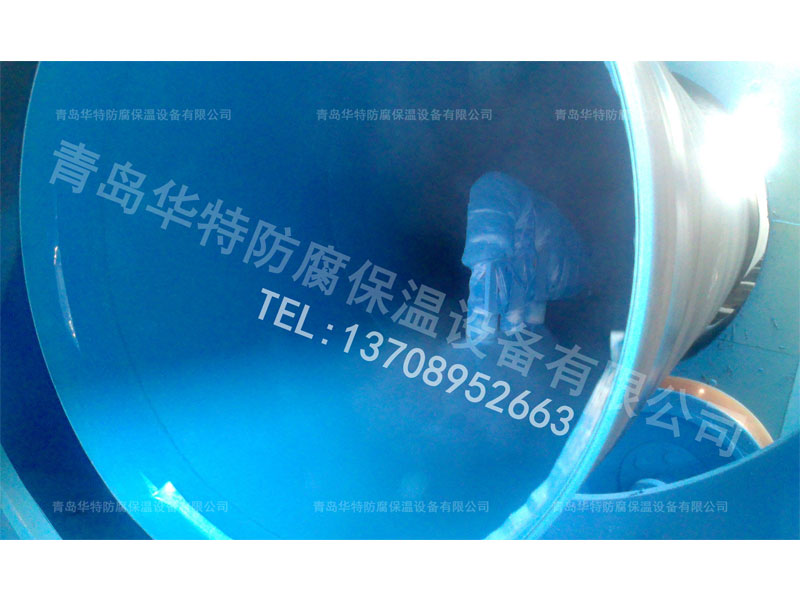

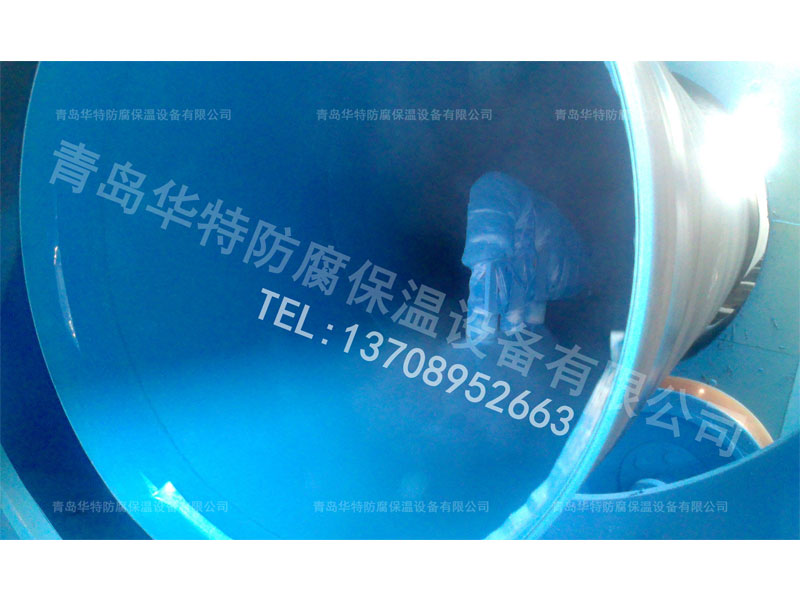

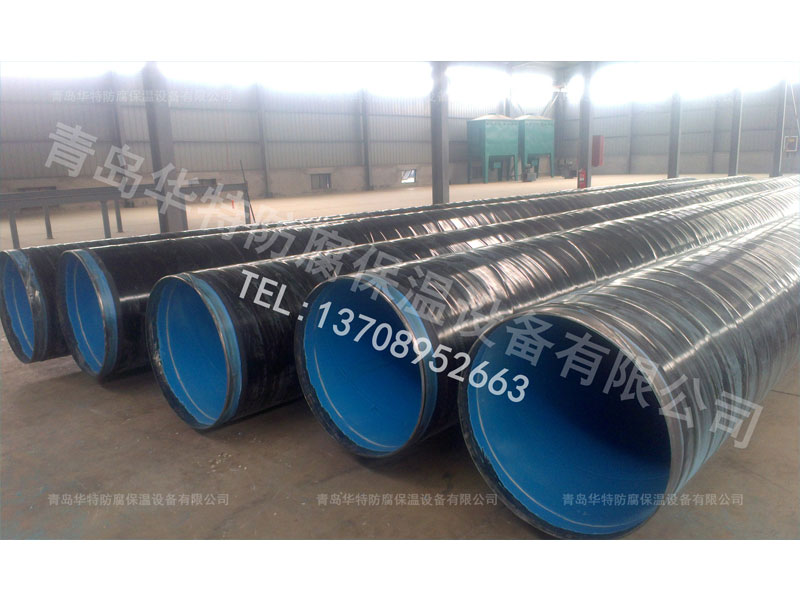

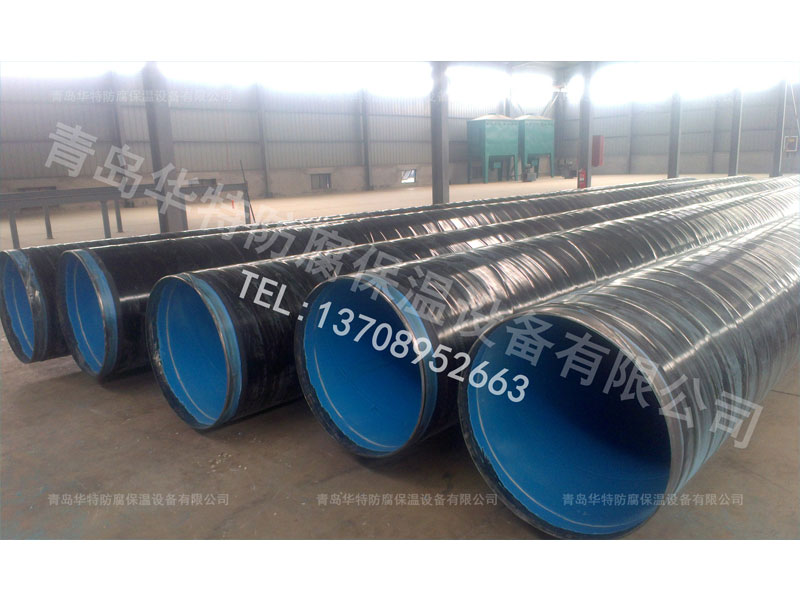

TPEP pipeline outer winding polyethylene fusion bonded epoxy anti-corrosion steel pipe, is the fourth generation of pipeline corrosion in the form is a specific kind of anti-corrosion technology,

TPEP pipe - outside the polyethylene internal corrosion protection pipe

TPEP pipeline outer winding polyethylene fusion bonded epoxy anti-corrosion steel pipe, is the fourth generation of pipeline corrosion in the form is a specific kind of anti-corrosion technology, the anti-corrosion materials used in pipeline corrosion protection is according to production process of custom-made, dedicated to pipeline anticorrosion.

(Inner wall anticorrosion: hot melt epoxy powder

Epoxy powder is a thermosetting powder coating, has the characteristics of corrosion resistance and toughness, based on steel substrate by heating the special epoxy powder evenly coated on the surface of the pipe body on, adhesion in the preheating pipe surface of epoxy powder heating gel advection, by continuing to heating, epoxy powder obtained fully cured, forming a continuous film, through and the surface adhesion of steel pipe, curing and provide good adhesion, has good resistance to chemicals and anti cathode stripping ability, is the large-scale pipeline project in China preferred coating.)

(Properties of epoxy powderInternal epoxy coating

Epoxy resin powder belongs to the polar molecules, thermosetting powder coatings, and heating temperature has a direct relationship, the reaction temperature of epoxy powder points as gelatinization temperature, curing temperature, gelatinization temperature than the curing temperature is low, when the gelling process coating only melt advection, did not produce the curing reaction, must continue within the prescribed time after once again heating epoxy coating can be fully cured, epoxy powder to curing temperature, reaction together with the steel substrate, adhesion is very strong, also epoxy resin is a kind of polymer material corrosion resistance ability is very strong, dense coating has good anti permeability. According to different coating process is divided into ordinary type of epoxy powder and pipe specific type of epoxy powder.)

(Outer wall anticorrosion: 3 layers of polyethylene

External 3PE coating

The bottom for the fusion bonded epoxy adhesive; middle layer; the surface layer of extruded polyethylene. In the three layer structure, the underlying epoxy powder is according to the production process of specific a special powder, its main function is: form a continuous film, and the surface of the steel pipe direct bonding, with good resistance to chemical corrosion and cathodic disbonding resistance; chemical bond formation and the middle adhesive layer the reactivity of functional groups to ensure overall anticorrosion layer under high temperature with good adhesion. The main function of the polyethylene surface layer is to protect the mechanical and corrosion protection, so as the buried pipeline, the outer protective layer is very superior. According to the data, three layer PE can make the life of the buried pipeline to reach 50 years, at present, in the world is considered to be the most advanced pipeline external corrosion protection technology.)

(Epoxy powder coating process

Epoxy powder coating process is divided into: electrostatic spraying, thermal spraying two kinds of technology.)

(Electrostatic spraying, solidification, air cooling

Ordinary type epoxy powder has a high volume resistivity, makes it easy to charged powder particles made of, via electrostatic powder spraying equipment, powder coating is sprayed onto the surface of the workpiece, in under the action of electrostatic, powder uniform adsorption on the surface of the workpiece, form the powder coating, powder coating through high temperature baking flow flat curing, the formation of the final coating; due to electrostatic spraying process, the coating thickness is relatively thin only in anticorrosion of thin sheet metal, is more and more used in home appliance industry.)

(Thermal spraying: spraying (gel) - heat curing - water)

(Pipeline special type epoxy powder special for pipeline corrosion protection, is a special powder according to the production process. Epoxy powder and heating temperature has a direct relationship, through the gelation temperature on steel substrate is heated to powder, epoxy powder evenly coated on the surface of the pipe body, adhesion in the preheating pipe surface of epoxy powder only gel advection, did not produce the curing reaction, we must continue to heat to the curing temperature of epoxy powder to produce the curing reaction and the coating and steel pipes are tightly combined with; so the process does not exist in the finished product reheating, just let the product complete the gel and curing reaction in different position, and ultimately the formation of fully cured anti-corrosion products. This process is the most of the current domestic pipeline corrosion manufacturers using the process, the reliability of its reliability has been the practice and verification.)

Cooling way of anticorrosion pipe

1、Cooling mode

The cooling way of anti-corrosion pipeline is related to the production process and the anticorrosion form of the product, and is divided into two kinds of cooling mode, air cooling and water cooling.

Air cooling is mainly used in the single layer structure of anti-corrosion pipeline, because of the single layer structure of anti-corrosion pipeline coating thin, through the use of internal and external air cooling can meet the cooling conditions of the coating.

(External water cooling is mainly used in the three layer structure of anti-corrosion pipeline, because of the three layer structure of the external coating thickness, heat conduction time is longer. Production can be either by controlling to the water quantity and water temperature, so that the tube body to slow cooling, so the use of external water cooling mode in the same time, can achieve single anticorrosion structure both inside and outside the air cooling effect; and for the purpose of water only from the outside of the pipe body cooling, cooling outer coating first cooled, through the conversion of energy and of the coating to the cooling, so water is not directly to the internal coating, but through the outer coating, tube body indirectly slow role to the inner coating.)

(Therefore, the role of the two types of cooling in two different coating, the cooling time is similar, there is no problem of cold, all belong to slow cooling. This cooling method is the most of the three layer of anti-corrosion pipe manufacturers in China.)

2、Of single pipeline corrosion by air cooling mode and three pipeline anticorrosion layer by water cooling, cooling rate were detected. Through the test, monolayer air-cooled and three layers of water-cooling gradient cooling curve is basically close to the (shown below). Through the cooling gradient curve, we can find that the effect of the two cooling methods on the two different coating, all belong to the slow cooling mode, which has no effect on the quality of the coating.

(Single layer cooling gradient curve)

(Three layer water cooling gradient curve)

3、Test and detection of two kinds of cooling methods

(Follow a day is equal to two months of simulation environment, coating of two types of cooling pipeline corrosion sample adhesion, corrosion resistance, resistance to cathodic stripping performance of 2400 hours of accelerated test, through the experiment, we found that:):

?The internal epoxy coating did not appear to reduce the adhesion and aging phenomenon.。

?Outside the single layer structure of the specimen accelerated test has not been carried out to 100 hours, the adhesion appeared significantly decreased。

?Outside the three layer structure of the sample after 2400 hours of accelerated test did not appear quality changes。

Through the analysis of the outer monolayer structure anticorrosion pipeline because of the production process, the outer coating is thin, and the adhesion performance and the resistance to the cathode stripping performance are not as good as the three layer mechanism anticorrosion pipeline.。

?conclusion

Antisepsis layer for the life of the pipeline is vital, pipes of the same material. Some were buried in the ground for decades and no corrosion, and some years occurred leak, because they use different anti-corrosion materials, corrosion and anticorrosion technology.

The internal corrosion protection material used in the outer wrapping of the internal fusion bonded epoxy anticorrosive steel pipe (TPEP pipe) is a special powder according to the production process. Epoxy powder and heating temperature has a direct relationship, through the gelation temperature on steel substrate is heated to powder, epoxy powder evenly coated on the surface of the pipe body, adhesion in the preheating pipe surface of epoxy powder only gel advection, did not produce the curing reaction, we must continue to heat to the curing temperature of epoxy powder to produce the curing reaction and the coating and steel pipes are tightly combined with; so the process does not exist in the finished product reheating, just let the product complete the gel and curing reaction in different position, and ultimately the formation of fully cured anti-corrosion products. This process is the most of the current domestic pipeline corrosion manufacturers using the process, the reliability of its reliability has been the practice and verification.

3PE anticorrosion layer integrated excellent properties of polyethylene anticorrosive layer of epoxy coating and extrusion, will the interfacial properties of the epoxy coating and resistance to chemical properties, and extrusion polyethylene anticorrosion layer mechanical protection characteristics combine the advantages, can improve their performance.

Cooling way is the vast majority of domestic and foreign three anti-corrosion pipe manufacturers adopt the cooling mode. Because of the three layer structure, the external coating is thicker and the heat conduction time is longer. Production can be either by controlling to the water quantity and water temperature, so that the tube body to slow cooling, water-cooled only from the outside of the pipe body cooling, cooling the outer coating first cooled and through the conversion of energy and of the coating to the cooling, so water is not directly to the internal coating, but through the outer coating, tube body indirectly slow role to the inner coating.